Induct-A-Ring FAQs

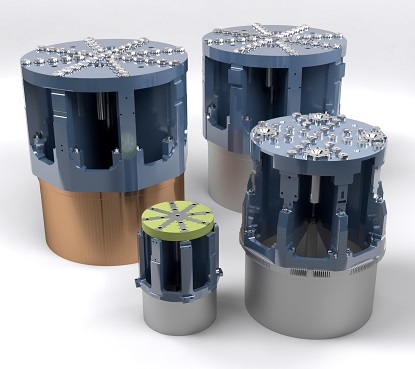

How big are Induct-A-Ring armatures?

How big are Induct-A-Ring armatures?

The T2000 shaker features a 17.5" diameter (444mm) armature while the T4000/5000/5500 series steps up to a 25.5" diameter (648 mm). For high frequency testing of small components such as turbine blades, the T208IAR has a smaller 9.25" (235mm) armature.

What kind of low frequency output can you get with Induct-A-Ring shakers?

Although operation to absolute DC is not possible, the useable low frequency range limit for all T2000 / T4000/T5000/T5500 shakers is 2 Hz. Full rated stroke is specified down to 5 Hz: 2 inch (51 mm) pk-pk std and 3 inch (76 mm) pk-pk optional. Note: 3” (76 mm) pk-pk is standard on the T5500. IAR shaker low-frequency performance meets or exceeds that of most wound coil shakers.

What about high-frequency performance?

IAR armatures have significantly higher resonant frequencies (Fn) than comparable wound coil designs. The IAR’s high-frequency performance advantage is tied to its solid metal construction and lack of epoxy joints in the moving armature. As a result of these superior Fn numbers, the T4000/T5000/T5500 shakers deliver full rated force to 2 KHz, while some T2000 system configurations deliver full rated force to 3 KHz! The T208IAR is designed specifically for high-frequency sine and random vibration (5 KHz +) with extreme SRS shock testing up to 10 KHz.

Why do IAR armatures have higher “max g” ratings than wound coil armatures?

The standard IAR armature structure is comprised of a solid metal, forged ring that’s bolted rigidly to its upper web casting, producing a mechanically preloaded metal-to-metal interface joint. This solid metal assembly contains no epoxied windings, current carrying flexures or water cooling hose fittings. Consequently, the solid metal IAR armature can tolerate extreme vibration and shock g-levels that typically destroy wound coil armatures.