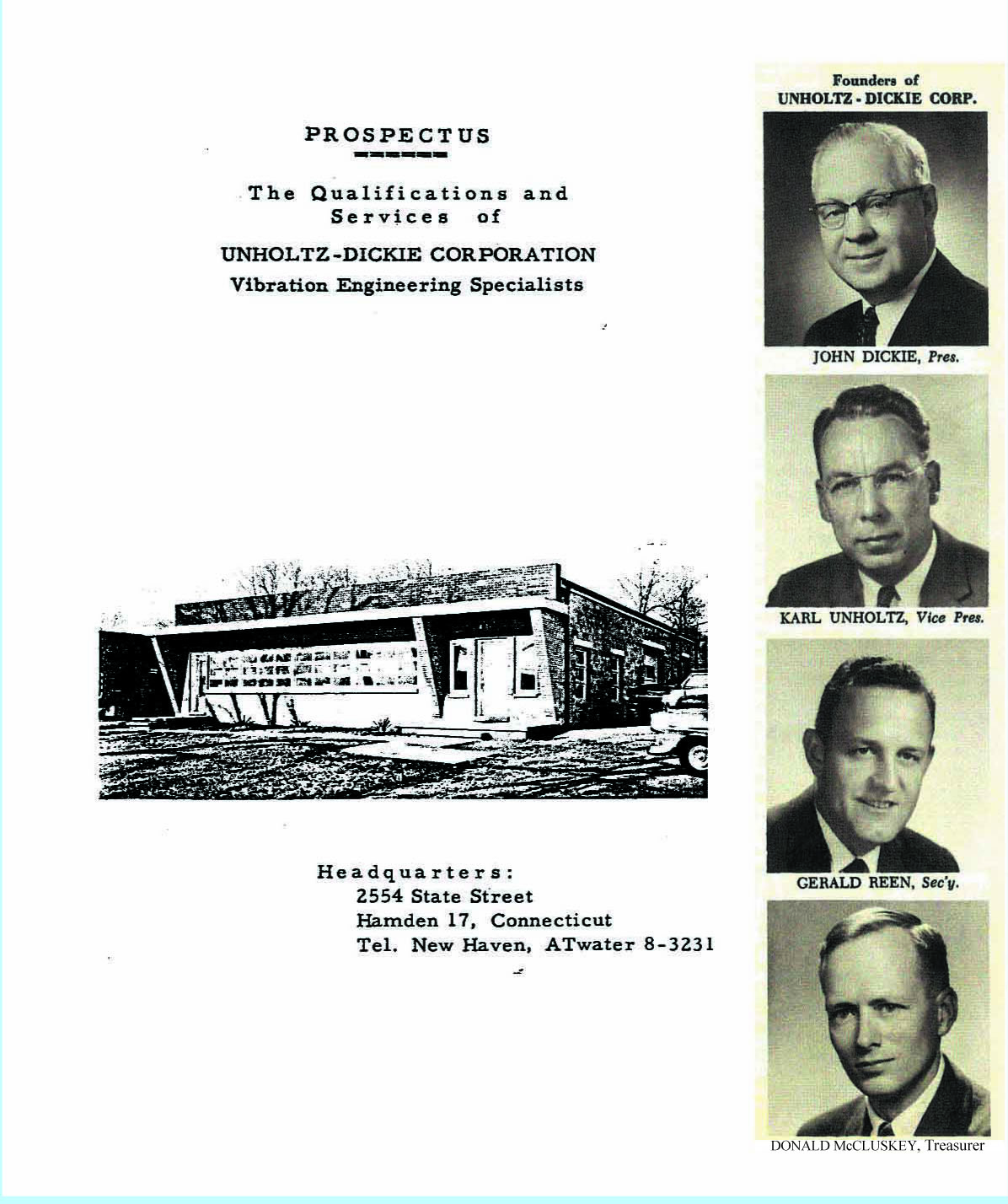

History

1940's

Karl Unholtz and John Dickie leave the Lockheed Aircraft Company and join the MB Company, located in New Haven, CT. In 1946, the first Electrodynamic Shaker (rated at 200 lbf) is built.

1950's

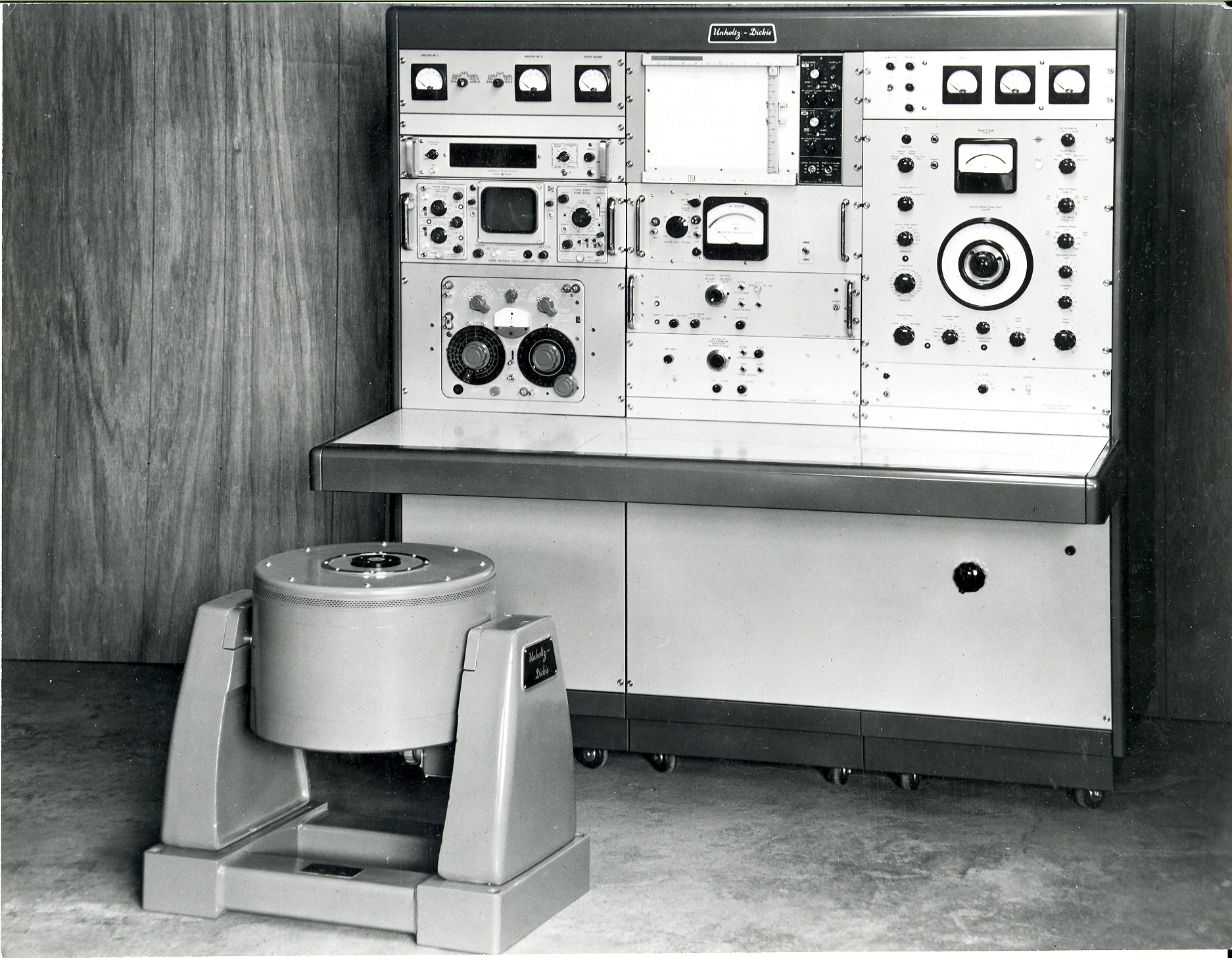

Gerry Reen and Donald McCluskey begin working as engineers at MB. In 1959, Mr. Unholtz, Mr. Dickie, Mr. Reen and Mr. McCluskey leave MB and start the Unholtz-Dickie Corporation in Hamden, CT. New shaker development took off, with the introduction of three new shaker Models; the Model 100 rated at 150 lbf, the Model 110 rated at 300 lbf, and the Model 106 Calibration Shaker. By the end of 1959, the first UD shaker system orders are received from GE-Canada and GE-Kentucky.

1960's

The 1960's brought numerous new products, innovations and industry firsts for newly formed UD Corp. These include Dial-A-Gain Vibration Instruments, Solid State Power Amplifiers in place of tube amplifiers, a line of accelerometers, and the first Modal Shakers (used to test the Boeing 747). UD's family of shakers broaden from 100-10,000 lbf. As business grows, UD opens a West Coast Sales & Service office in California, and begins supplying shaker equipment that supports the space race to the moon. In 1969, UD engineers begin design of a radical new shaker armature called Induct-A-Ring, and begin testing the first ever T1000IAR (rated at 10,000 lbf). To this day, the UD Induct-A-Ring shaker continues to outperform and outlast the competition. To date, UD has built over 1,000 UD IAR Shakers.

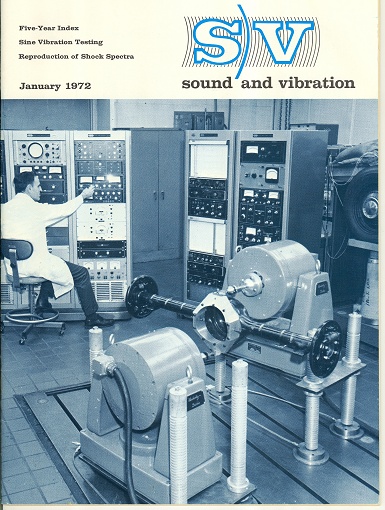

1970's

The 1970's continue to bring about expansion and change for the company. In 1977, UD introduces the first 40,000 lbf Shaker System ever built and exports two T4000 shaker systems to Germany. In 1979, UD moves from its rented Hamden, CT facility to a newly built, custom designed factory and World Headquarters in Wallingford, CT. Other developments include a full range of multi-channel analog instruments for sine and random testing, the CSTA Series Combined Slip Table Assembly, and UD's first transducer calibration system, a system that becomes an industry standard for the U.S. NAVY and other defense organizations. UD's family of shakers now range from 50 lbf to 40,000 lbf.

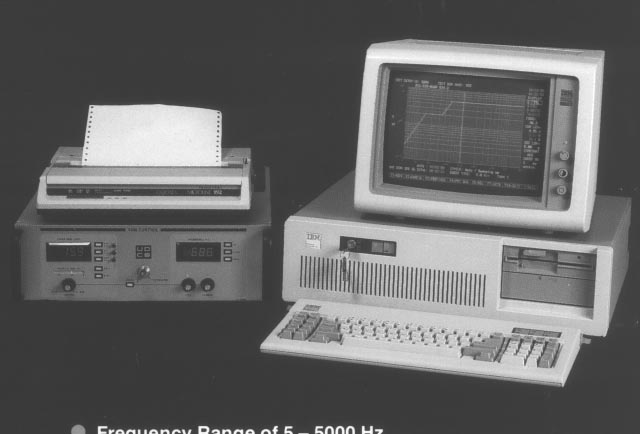

1980's

As demand for vibration test systems increases, UD adds on to the CT factory, nearly doubling production capacity. UD begins offering the 560 Series shaker, which becomes one of the most popular mid-range shakers in the industry. The economical ST Series slip table assemblies are introduced, allowing sequential vertical and horizontal testing. In 1986 UD ships the first Automobile Air Bag Crash Sensor Test System (Model 4, followed closely by the Model 6X). And in 1987, UD opens its first European office in Germany, and introduces the first PC based Vibration Controller, the 400AT. CAD design tools are put to use in new shaker and amplifier designs.

1990's

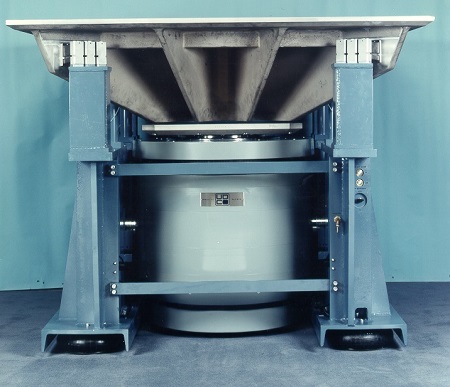

UD introduces the 50,000 lbf T5000 Shaker, the first one shipping to a US Government Test Facility in New Mexico. In 1991, UD begins production of Class D Air Cooled Switching Amplifiers utilizing MOSFETS, and in 1994 ships the first Buzz, Squeak and Rattle system (shown here) to Ford Motor Company. In 1995 UD offers the industry's first Microsoft Windows based vibration controller, the Vwin. Design and development begins on a full line of new S-Series shakers. These economical, single ended shakers include one field coil, providing an immediate cost savings for commercial grade testing. The shaker export market begins to flourish in the mid 90's, and UD expands with sales to over 20 countries, including China.

2000-2009

In 2000, UD introduces the first power amplifiers using high efficiency, Insulated Gate Bipolar Transistors (IGBT's). In 2003, 3-inch stroke capability for medium to high force systems are offered, then UD supplies the first ever electrodynamic seismic test system (12 inch stroke) designed to simulate earthquake conditions on communication racks. In 2006 UD delivers the first 55,000 lbf system, the Model T5500, and soon after develops a complete family of head expanders for large product testing. And in 2009, UD develops the first shaker to generate 1,500g shock pulses for sensor and hard disk drive testing (S092-UX).

2010-Today

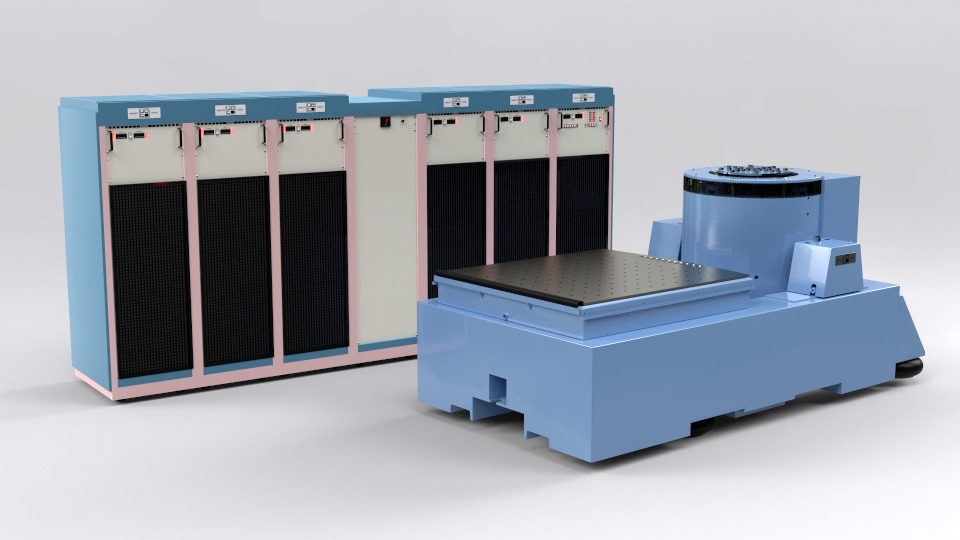

UD releases two new shaker models; the highest force, all air cooled K-Series rated at 18,000 lbf, and the compact 5,000 lbf S402 designed for assembly line integration. A new HST Hybrid Slip Table base with bearings debuts, and the all new Apex SL Digital Vibration Controller is released as the successor to the popular Vwin II. Also, in 2010 UD ships the highest capacity shaker amplifier ever built, the 2XSAI360, rated at an astounding 720 KVA. Combined with the T2000 shaker, this system provides extreme level SRS testing. In 2016, UD reaches another major milestone, shipping the 1,000th Induct-A-Ring shaker to a prominent Aerospace Company. In 2018 UD receives a single purchase order for 25 shaker systems, the largest order in its history. UD starts 2019 with its largest number of open orders ever and proudly celebrates the company's 60th anniversary!!