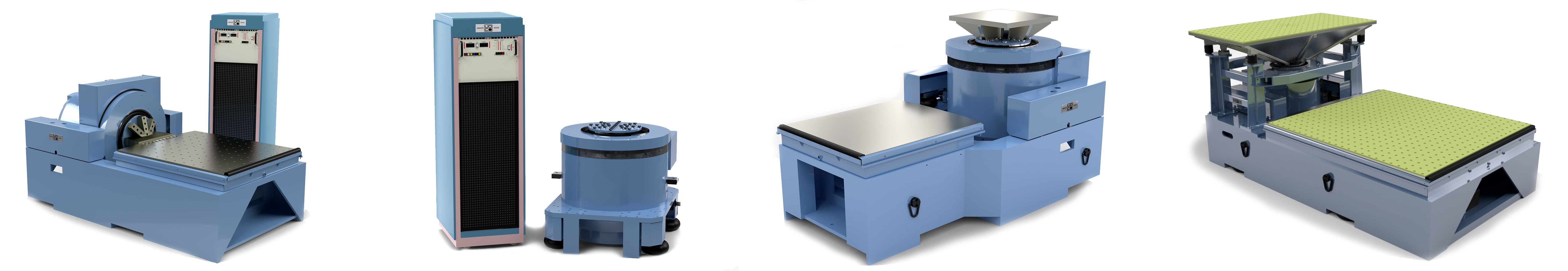

R-Series Electrodynamic Shakers

The R-Series vibration test systems are designed to provide reliable performance for medium and high force applications. The R-Series Shaker Armature incorporates a multi-ribbed design, which provides maximum stiffness and minimum weight, resulting in a high acceleration to specimen weight ratio and impressive acceleration and frequency performance.

The R-Series vibration test systems are designed to provide reliable performance for medium and high force applications. The R-Series Shaker Armature incorporates a multi-ribbed design, which provides maximum stiffness and minimum weight, resulting in a high acceleration to specimen weight ratio and impressive acceleration and frequency performance.

The vibration test systems consist of the SAI Series Class D power amplifier, R16 or R24 electrodynamic shakers, DC field supply, and remote cooling blower. Many standard features are included such as an EMI shielded console with AC line filtering and full featured interface panel for the power amplifier, interface cabling with military style connectors, internal load support and automatic armature centering, and integrated safety interlocks. All systems are direct coupled and require no transformer re-connections or switching circuits for full rated performance.

Features

- Max force 10,000 – 13,500 lbf (44.5 to 60 kN) depending on configuration

- Two armature sizes available:

- R16: 17.5 inch (445 mm) diameter

- R24: 25.75 inch (654 mm) diameter

- Armature weight with inserts:

- R16A: 80 lbs (37 kg)

- R16C: 100 lbs (45.4 kg)

- R16C-2.5: 110 lbs (50 kg)

- R16CA-3: 130 lbs (59 kg)

- R24A: 125 lbs (57 kg)

- R24C: 145 lbs (66 kg)

- 200 "g" shock

- 2 inch (51 mm) displacement; 3 inch (76 mm) optional (R16 only)

- 1,500 lbs (680 kg) internal pneumatic load support

- Extra heavy-duty armatures

- Three base configurations:

- Completely air-cooled

- Modular, high-efficiency class D power amplifier

- Ultra-rugged, reliable Silicon Carbide (SiC) MOSFET Technology

- Combined environment support

- Optionally available “Quiet Mode”

- APEX SL control systems

- SA-Command Link APEX SL / amplifier remote interface

Air-Cooled

All of the standard R-Series vibration test systems are totally air-cooled, an important feature that boosts reliability and reduces the cost of installation and operation. Both the SAI Series power amplifier and the R-Series electrodynamic shakers are cooled by forced air.

Rugged, Lightweight Armature

Cast from a high-strength magnesium alloy, the R16C and R24C armatures are known for their robust design and long term reliability. These armatures feature a multi-ribbed table for maximum stiffness and minimum weight. The high strength construction and low weight of these armatures provide superior acceleration to specimen weight ratios. The R16 can be configured with an Aluminum Armature Coil ("A" configuration), providing higher frequency performance, while the "CA" configuration offers a combination of high force and high frequency performance.

2 inch (51 mm) Displacement; 3 inch (76 mm) Optional

The R Series shakers are rated for 2 inch pk-pk displacement, a requirement for many of today’s transportation and long duration shock tests. Optional 2.5 inch (63 mm) and 3 inch (76 mm) R16 shakers are now available.

Internal Load Support

1,500 lbs (680 kg) internal pneumatic load support including automatic armature centering is provided as standard for test specimen and fixture support.

Industry Applications

The R-Series vibration test systems are considered the standard for testing medium to large products in several major industries, including automotive, aerospace, aircraft, communications, computers, defense and electronics.

Typical test applications include: product development, stress screening, accelerated life testing, in-service environment simulation, product qualification and certification, and transportation testing.

Typical products include: single & multiple circuit boards, power supplies, receivers, transmitters, desktop and portable computers, printers, monitors, and other computer and communication products.

For automotive applications, the R-Series is used for testing HVAC units, door panels, radiators & condensers, alternators, fuel rail assemblies, instrument panels, engine and suspension components.