ST Slip Table Assemblies

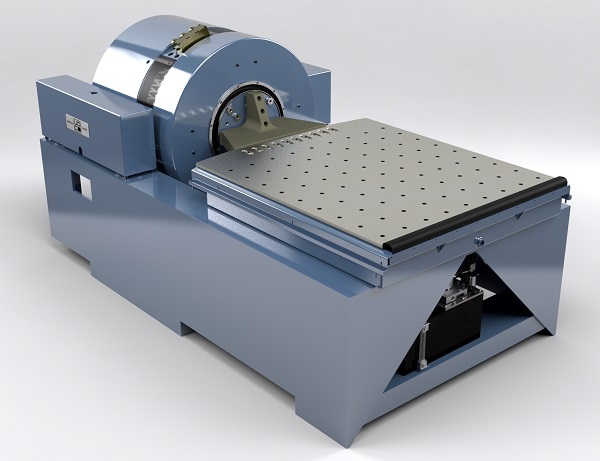

The ST Series Slip Table Assembly is one of three base configurations offered by Unholtz-Dickie for its vibration test systems. It is ideally suited for sequential 3-axis test capability with minimized cross axis response; for testing heavy, oversized, or non-symmetrical loads; and for products where orientation with respect to gravity is necessary.

The ST Series Slip Table Assembly is one of three base configurations offered by Unholtz-Dickie for its vibration test systems. It is ideally suited for sequential 3-axis test capability with minimized cross axis response; for testing heavy, oversized, or non-symmetrical loads; and for products where orientation with respect to gravity is necessary.

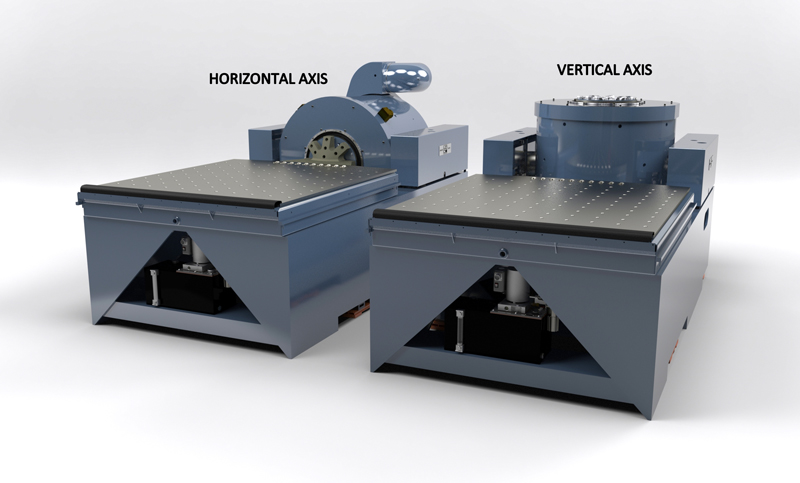

A unique trunnion and guidance bearing assembly (IGIS) provides simple shaker rotation capability and body vibration isolation. The electrodynamic shaker can be rotated to the vertical position for one axis and then to the horizontal position where it is connected to a horizontal slip plate for the other two axis testing. Ambient and Combined Environment (vibration/thermal) testing are both supported. The ST Series slip table assembly offers many advanced features that are unsurpassed in this type of base configuration.

ST Design Evolution

The concept of an integrated shaker and slip table base was pioneered by Unholtz-Dickie Corporation in the early 1960s. The design followed requirements for sequential three axes testing with common fixtures. By combining the electrodynamic shaker and slip table base, Unholtz-Dickie offered a vibration platform with superior cross axis performance compared to separate base designs. This also provided a more convenient configuration for converting between test axes.

The concept of an integrated shaker and slip table base was pioneered by Unholtz-Dickie Corporation in the early 1960s. The design followed requirements for sequential three axes testing with common fixtures. By combining the electrodynamic shaker and slip table base, Unholtz-Dickie offered a vibration platform with superior cross axis performance compared to separate base designs. This also provided a more convenient configuration for converting between test axes.

The combined base also provided a stiffer and more reliable base structure; a design that was specifically engineered to resist pitching and bending modes thus increasing the overall reliability. The ST Series Slip Table Assembly is the newest generation of combined slip table assemblies offered by Unholtz-Dickie. Its design was refined from years of experience applying integrated base technology to customer’s testing needs. The ST Series Slip Table provides superior dynamic performance, high reliability, and many user-oriented features that reduce test setup effort and enhance productivity.

ST Series Design Advantages

The Unholtz-Dickie ST Series integrated shaker/slip table design offers numerous critical technical features compared to other manufacturer's integrated base designs and especially compared to the low cost but very limited "combo" base designs (shaker and standalone slip table mounted on a common steel plate). These features result in superior long-term reliability and durability, performance, structural integrity, building isolation, and simplified operation.

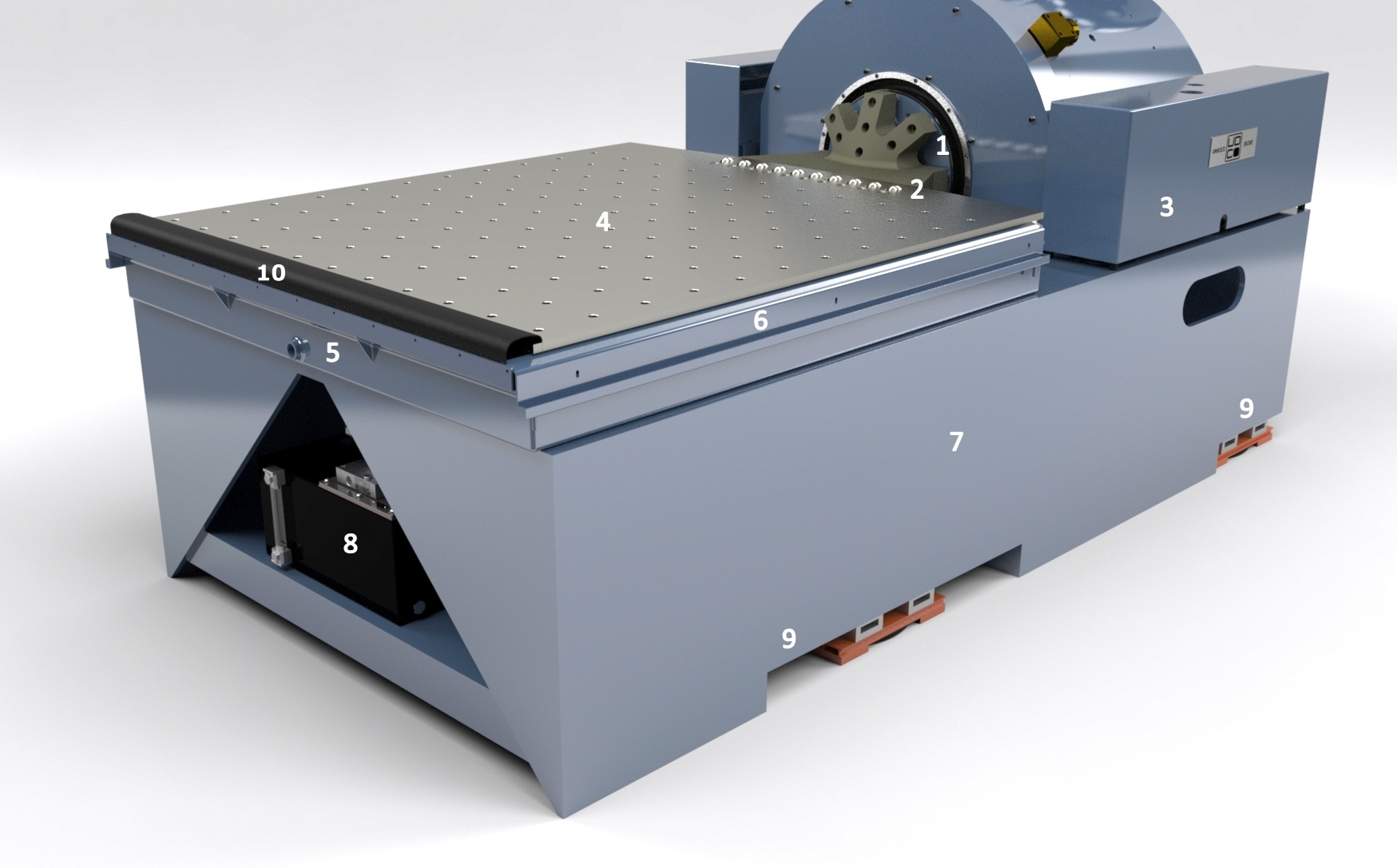

- Shaker Armature

- Compression Step Driver Bar

- IGIS Isolation & Guidance

- Magnesium Slip Plate

- Oil Return Basin

- “Oil Guard” Protection

- Heavy Duty Steel Base

- Multi-Port Hydraulic Pump

- Slots for Fork Lift Access or Optional Air Slide

- Flexible Rubber Boot - Oilguard Protection

Rigid Steel Base

The ST Series base is fabricated from rigid, dimensionally uniform steel plates with generous sectional reinforcements. The robust construction and increased mechanical stiffness result in minimized pitching and torsional responses that are characteristic of stepped or non-integrated base designs. These desirable ST features equate to better control of the vibration test and extended service life.

Granite Bearing Support

The high mechanical stiffness of the supporting granite is transferred to the magnesium slip plate by adhesion of the oil film acting over the entire granite surface area. The use of flat ground granite (not manmade synthetic granite) eliminates surface imperfections that can score the underside of the slip plate and cause distortion of the vibration waveform. Real granite eliminates the inherent problems of flatness, smoothness, and wearing associated with the cheap “synthetic granite.”

Permanently Aligned

The integration of the shaker and ST Series base is accomplished at the factory using specialized tooling. The process is permanent and ensures that the shaker and base will always remain true and aligned with respect to one another no matter the orientation: a Permaline configuration. Permanent alignment is especially critical for those testing situations when the shaker will be rotated between vertical and horizontal modes many times throughout its service life.

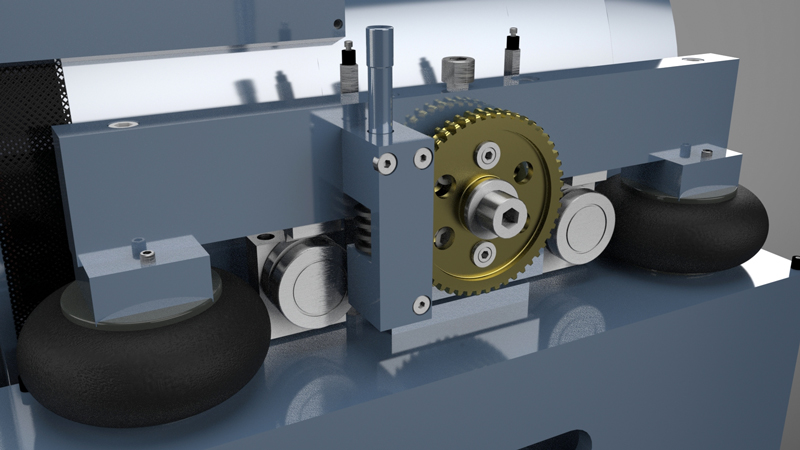

Shaker Guidance and Isolation

Because the shaker must function in both the vertical and horizontal orientations, Unholtz-Dickie has developed an automatic Integrated Guidance and Isolation System, IGIS. This system automatically adjusts itself for vertical and horizontal operation. Air springs automatically lift and support the shaker for vertical operation using air damping tanks to provide effective isolation above 5 Hz.

Because the shaker must function in both the vertical and horizontal orientations, Unholtz-Dickie has developed an automatic Integrated Guidance and Isolation System, IGIS. This system automatically adjusts itself for vertical and horizontal operation. Air springs automatically lift and support the shaker for vertical operation using air damping tanks to provide effective isolation above 5 Hz.

Air springs are automatically deflated when the shaker is positioned in the horizontal orientation bringing the shaker to rest on a set of grooved linear bearings that provide precise alignment and serve to decouple the shaker body from the base. Passive elements provide a centering force. The IGIS design effectively minimizes the vibration transmitted to the surrounding area.

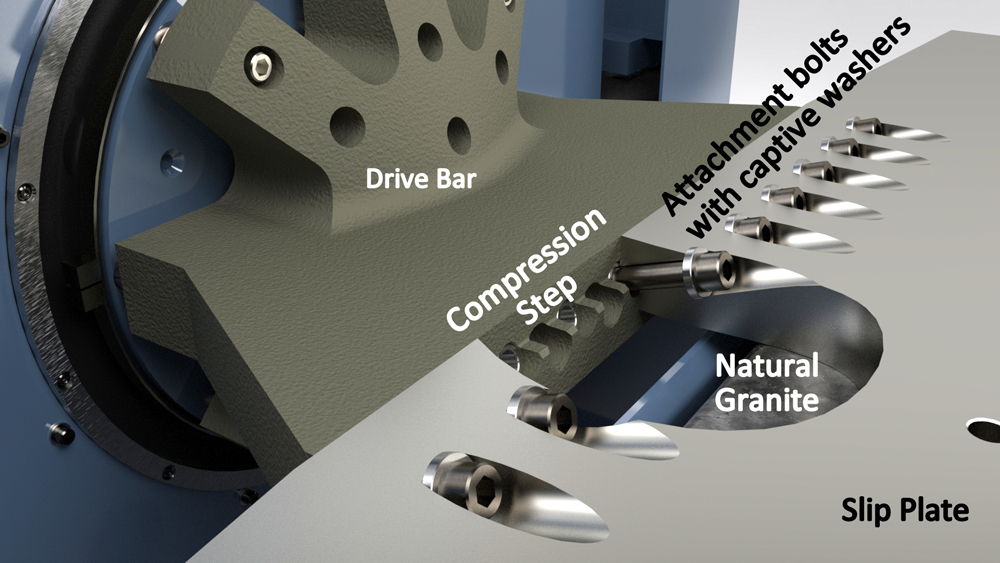

Cast Magnesium Driver Bar

A cast magnesium driver bar joins the shaker table and the magnesium slip plate. The cast driver bar provides a stronger, more reliable attachment than welded driver bars and eliminates inherent weaknesses associated with welding such as insufficient penetration, root cracks, blow holes, and heat effected zones.

Compression-Step Interface

The Compression-Step design was first offered by Unholtz-Dickie. It provides a large distributed mating surface area, preloaded in compression, and demonstrates greater transmissibility between the shaker and slip plate than split ring and orthogonal designs. Angular orientation of the fasteners produces compression forces across all mating surfaces giving superior dynamic performance and makes the driver bar connection an operator-friendly procedure.

The Compression-Step design was first offered by Unholtz-Dickie. It provides a large distributed mating surface area, preloaded in compression, and demonstrates greater transmissibility between the shaker and slip plate than split ring and orthogonal designs. Angular orientation of the fasteners produces compression forces across all mating surfaces giving superior dynamic performance and makes the driver bar connection an operator-friendly procedure.

Constant Volume/Multi-Port Oil System

A constant volume multi-port hydraulic system is supplied as standard with the ST base and is easily accessible. This system provides oil to the slip plate/granite interface from underneath the granite support eliminating interference problems associated with designs where oil feed lines are external to the slip plate. The constant volume multi-port design ensures that a constant volume of oil is supplied at each feed site under the slip table and thus reduces the possibility of localized oil starvation even when the test package CG is located near the end of the plate away from the shaker.

Oilguard

Unholtz-Dickie has developed a new feature to solve the age old problem of having unwanted water and foreign particles from entering the slip table re-circulating oil. Contaminants increase oil replacement frequency, require additional maintenance and decrease reliability. Oilguard effectively covers all exposed areas, reducing the possibility of slip table oil contamination.

Oilguard Details

Slip plates have been enlarged to cover the entire back area of the granite.

Combined Environment Testing

The ST Series was designed to support both ambient and combined environment testing. The ST Series can be integrated with thermal/humidity chambers supplied by all of the leading thermal chamber manufacturers, domestic and foreign.

Optional Interface Items

A two-stage silicon blanket including stainless steel standoffs is supplied for vertical operation (orange and black). A sheet of G10 insulating material (green) is rigidly bolted to and covers the full surface of the slip table for horizontal operation.

An air slide system is available for easily moving the ST Series base assembly. The system uses shop air to float the base, allowing convenient positioning of the ST with respect to the chamber.